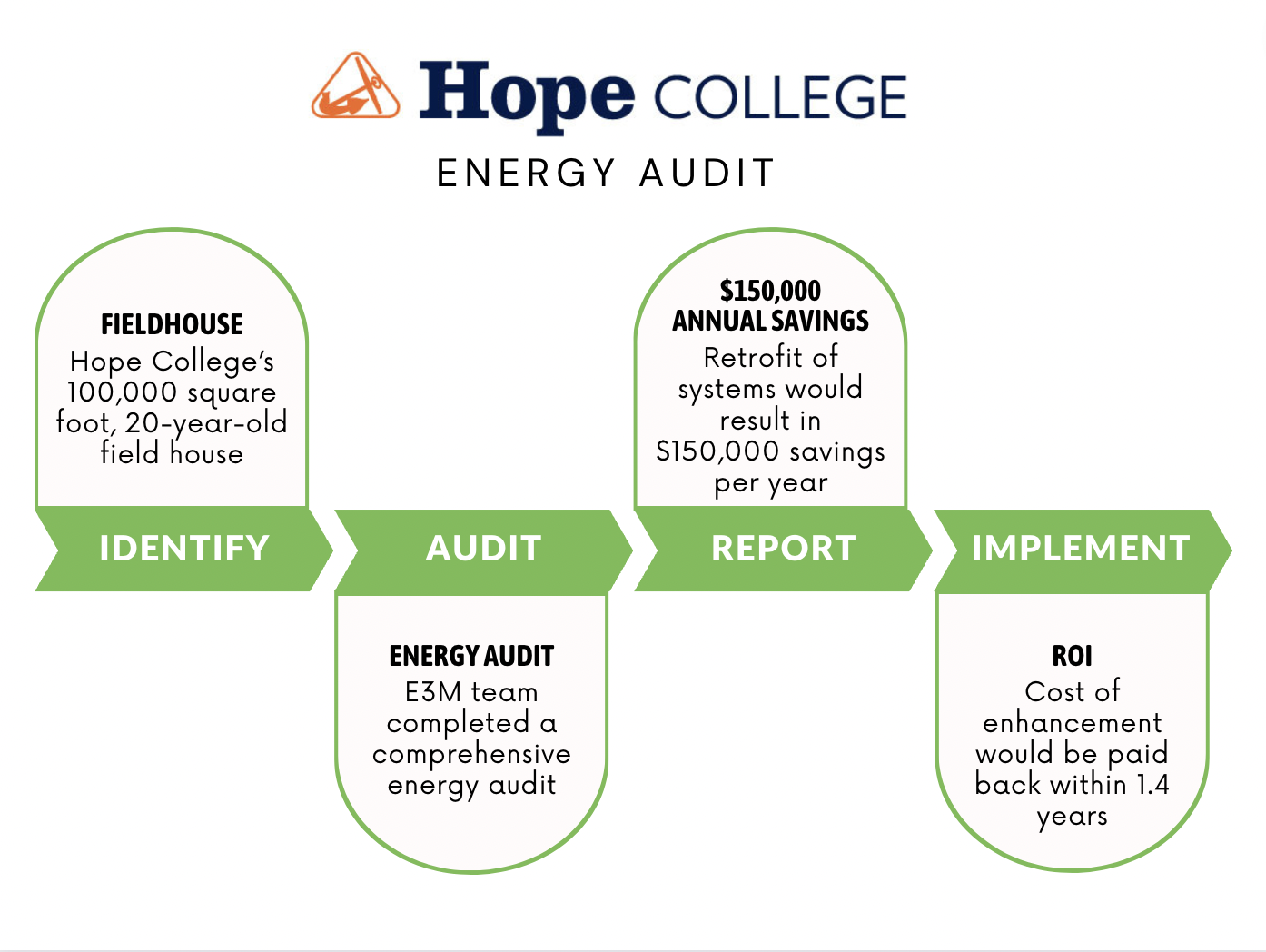

Hope College—located in Holland, Michigan—worked with E3M to complete a building energy audit for their DeVos Fieldhouse. This is a NCAA Division III athletic facility of approximately 105,000 square feet. It consists of a sports arena, weight-training facility, classrooms, concessions, and administrative offices.

The building was constructed in 2005 and has received some updates to equipment and lighting fixtures, but the team suspected there was room to improve energy efficiency. They were receiving very high energy bills for electric and natural gas. Their natural gas provider, SEMCO connected them to E3M to see what energy efficiencies could be achieved for the building.

The original scope of the project was to complete an energy audit, similar to ASHRAE Level 1 which identifies and calculates energy savings for their equipment that consumed natural gas. SEMCO provided the funds through one of the rebate programs they offer to pay for the audit. Once E3M got started, the energy audit provided was closer to an ASHRAE Level 2 scope of work, as we identified additional areas of benefit for Hope.

E3M’s process:

- Documentation: We requested Hope College’s construction documents and past energy bills for review.

- Site audit: We visited the DeVos Fieldhouse to analyze their current equipment and conditions, seeking to understand the building’s MEP system’s sequence of operations.

- Calculation: We then calculated Facilities Improvement Measures (FIM) and Energy Efficiency Measures (EEM), two procedures that help us prepare recommendations for a return on their investment.

- Report creation: Finally, we shared our findings with the Hope College team and were available for any questions they had.

Results of Hope College’s energy audit

Through this energy audit, we identified many solutions Hope College can implement for energy savings. The main three were lighting controls, snowmelt, and HVAC equipment scheduling.

Lighting controls:

- Issue: By default, the lighting in the arena, auxiliary gym and volleyball court are on when not in use. The current lighting controls only permit competition-level brightness during regular daytime hours (about 4,092 hours per year).

- Resolution: We recommended that Hope College allow the primary arena lighting to be adjusted to lower levels during regular use. Proposed lighting control modes involve setting the lights at 90% (current), 50% for 3,000 hours, and 90% for 900 hours.

Snowmelt:

- Issue: Currently, the snowmelt system operates on an outside air temperature (OAT) enabled setpoint, with three snow sensors across campus. And the current slab sensor is disabled as it is not reliable.

- Resolution: We suggested Hope College improve their snowmelt system by adding snow slab sensors at the North, West, East, South points. This will provide a more accurate indication of when the slabs are dry, allowing the system to dismiss the need for melting. Additionally, having slab temperature sensors will benefit the control of water temperature.

HVAC equipment scheduling:

- Issue: Most Air Handling Units (AHUs) are running constantly without schedules, leading to excessive energy use, equipment wear, and higher maintenance requirements.

- Resolution: We encouraged Hope College to manage schedules for AHUs and their associated Exhaust Fans (EFs). We also suggested ensuring that the programming includes unoccupied heating and cooling setpoints and the correct sequence of operations. The team can also implement reduced operating hours, targeting 80 hours per week for each AHU.

“In previous energy audits, we received results that either didn’t need an engineer to identify or would take decades to receive a payback. But with E3M, we received real numbers and true action items,” said Kara Slater, director of operations at Hope College.

“They went back to the original construction design to examine what equipment is reaching the end of its life cycle. Even better, they asked what we would do differently if we were designing the building now—rather than assuming everything is running the way we want it to.”